Akira Koiso

Electronics Engineering Department

Nikon Core Technology Center

Joined Nikon in 1974. Worked in camera manufacturing division for 10 years assembling and adjusting SLR cameras. Transferred to electronic imaging products factory in 1985. Currently responsible for manufacture of electronic circuit boards for coordinate measuring machines and IC steppers and scanners, etc. Appointed Nikon Master Craftsperson in 2011.

Akira Koiso is responsible for the manufacture of electronic circuit boards that are used in industrial equipment such as coordinate measuring machines and IC steppers and scanners. He solders numerous electronic components, such as integrated circuits (ICs), resistors, and condensers, to printed-circuit boards (PCBs), in order to finish the electronic circuit boards.

The production of electronic circuit boards consists of both automated processes and a manual soldering process.

In the automated soldering process, solder paste is smeared on the PCB, an auto-mounter mounts the electronic components on the PCB, and then the PCB is heated and cooled in a reflow furnace. In the manual soldering process that follows, components that cannot be mounted using an automated process are mounted by hand. Mr. Koiso is responsible for supervision of the automated processes as well as for the manual soldering process.

Due to improved miniaturization and heat-resistance, it is now possible to solder many electronic components using an automated process. However, there are electronic components that are not amenable to automated processes by reason of their size or shape. Manual soldering also represents the only means for replacing electronic components on an already completed electronic circuit board. Thus, manual soldering still remains an indispensable technique.

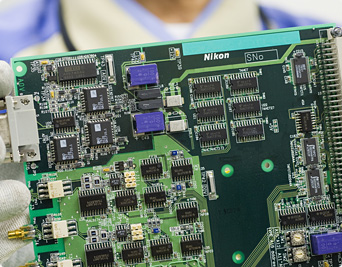

Fine manual soldering carried out by a technician looking through a stereoscopic microscope.

Many hundreds of electronic components may be mounted on a PCB.