Hisashi Sasaki

Manufacturing Technology Department, Production Technology Headquarters, Nikon Core Technology Center

Joined Nikon in 1975. Since then, he has been engaged in the work of machine inspection. Appointed as a Nikon Master Craftsperson in 2009.

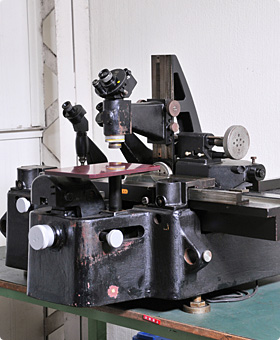

The UMM (universal measuring microscope)—the earliest standard measuring instrument in Nikon's possession. Made in Germany, it was transported to Japan during World War II aboard a German submarine. Mr. Sasaki used this for machine inspections right up until 1997.

Mr. Sasaki is unique among Nikon Master Craftspersons in that he is not directly involved in production. How, then, does he support manufacturing at Nikon?

When we asked him for details about machine inspection, he replied that it entails verifying whether measuring instruments used at production sites meet their specifications.

At the machining plant, for example, materials must be worked so that their dimensions are as specified in the blueprint. After processing has been completed, the shape and dimensions of the product are measured in order to ascertain whether they are within the specified tolerance limits. Unless the measuring instruments required for this operation yield precise measurements, it is impossible to check the degree of accuracy of the processing and impossible to maintain product quality.

Nikon uses various types of measuring instruments at its production sites, including vernier calipers, micrometers, industrial microscopes, and 3D Metrology. The craft of checking and ensuring the accuracy of these instruments is known as "machine inspection."