The surface plate inspection process

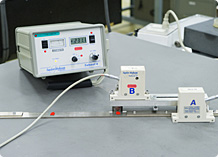

1.The surface of the surface plate is cleaned, and the inspector then verifies that it is horizontal using a level. The inspector then places the guide bar on the surface plate lengthwise.

2.The inspector places the fixed-position electronic level at the end of the guide bar and then fixes the measurement level in place at each measurement point in turn (as shown by the orange marks).

3.The inspector measures seven points in each direction (although this will vary according to the size of the surface plate).

4.The guide bar is now placed widthwise across the surface plate, and the inspector measures each point.

5.The guide bar is now placed diagonally across the surface plate, and the inspector measures each point. The process is repeated for the other diagonal.

6.The measurement results for all four directions (lengthwise, widthwise, and the two diagonals) are verified, and the process is complete.