Seiichi Yamagishi

First Production Division, Kurobane Nikon

Joined Nikon in 1978. Posted to the Nikon Yokohama plant and put in charge of polishing objective lenses for microscopes; transferred to the Nikon Group's Kurobane Nikon Co., Ltd. in 1998. Certified as Nikon Master Craftsperson in 2007.

Objective lenses for biological microscopes: CFI Apo TIRF 60xH and CFI Apo TIRF 100xH

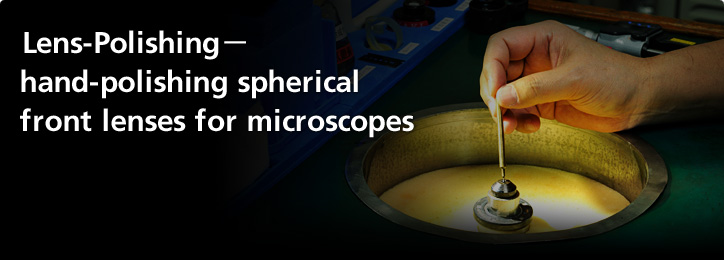

Mr. Yamagishi is in charge of polishing the front lenses of objective lenses for microscopes. The lens element on the tip of an objective is known as the "front lens."

The smallest of these lenses has an aperture of between 1 mm and 2 mm. There are some that have a distinctive shape that is midway between spherical and hemispherical.

The objective lens of a microscope forms an enlarged image of the microscopic object under observation, and must have a short focal length in order to achieve a high degree of magnification. In order to obtain a distinct image, the lens must also capture as much light as possible. Hence, the front lens has a distinctive shape with a high degree of curvature.

Lens-polishing is becoming increasingly mechanized. However, it is difficult to entirely mechanize the polishing process for front lenses due to their distinctive shape, the high precision required and the variety of shapes. Mr. Yamagishi says that at present the best method is to shape the lens as required by the design by hand-polishing those parts that cannot be left to a machine. In recent years, however, the increasing digitization of observation (in terms of the use of monitors that make use of image-sensing devices such as CCDs) has led to demand for higher-precision objective lenses. Despite the name, the acceptable tolerance limits for "hand-polishing" are no more than a few micrometers.