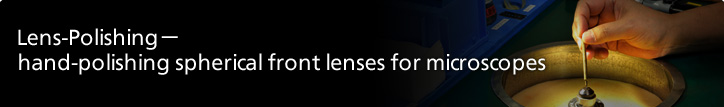

The hand-polishing process

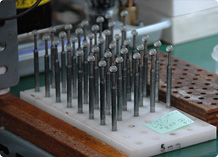

1.After undergoing pre-processing such as lapping, the front lens is attached to the tip of a metal rod known as a "hand-polishing rod." The front lens shown in the photograph has an aperture of around 5 mm—relatively large for a front lens.

2.Polishing equipment is sometimes used for processes other than the final polishing, such as lapping. However, in order to achieve the distinctive shape of the front lens, a final hand-polishing is required.

3.The center of the work stand is the polishing stand. Hand-polishing is carried out by pressing the lens onto the polishing plate. The polishing plate is rotated anti-clockwise, while the polishing rod is rotated clockwise. Rotating the rod at the precise speed and angle necessary requires skill.

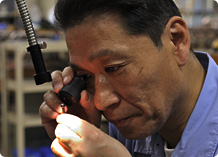

4.A loupe is used to check the surface of the lens for scratches.

5.The dimensions are precisely regulated using a micrometer.

6.A fully polished front lens. The smooth curvature of the surface and the high degree of transparency are something to behold.