Software

Capabilities and precision enhanced yet operation easier

- Edge detection with excellent precision

- Advanced intelligent search

- User-friendly standard software: VMR AutoMeasure

-

- Main program

- Interactive teaching wizards

- Interactive measurement wizards

- Online CAD interface program

- CAD interface off-line teaching support program: NEXIV Virtual AutoMeasure

- Two-dimensional profile shape analysis program: NEXIV Profiler

- Report generating program: VMR Report Generator

- NEXIV VMR Control Program

Edge detection with excellent precision

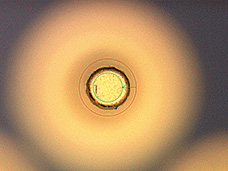

Gray scale processing via video edge probes

The black and gray portions of a workpiece are digitally classified into 256 gradation levels, then edges are detected and processed based on this classification. This prevents measurement data from being affected by changes in illumination.

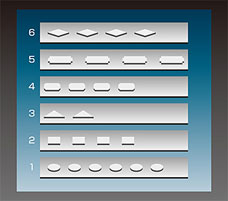

Video edge probes with auto "best-fit" function

When the operator clicks the point to be measured, the system automatically rotates the probes, sets them at the optimum position, and sets the probe size, all automatically.

Drag to resize and fit the projection probe to the edge

After this process

Drag to resize and fit the circle probe to the circle

After this process

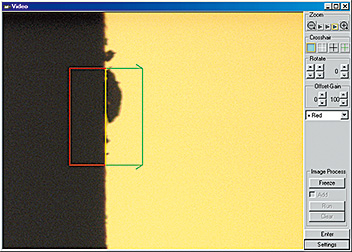

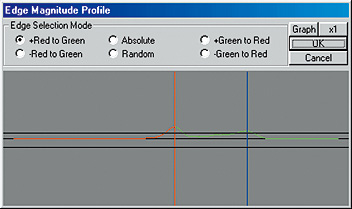

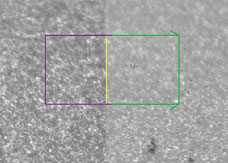

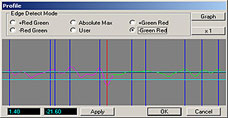

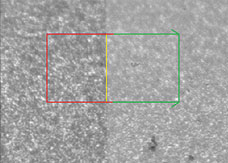

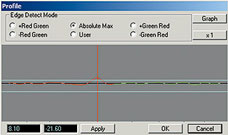

Easy selection of desired edges by eliminating dust and burrs

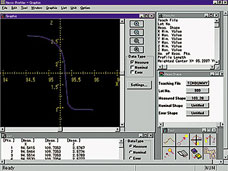

Some workpieces contain multiple edges within a given caliper, or their contrast is too low, making edge detection extremely difficult. This function graphically profiles the contrasts of the image within the caliper using a multi-gray-level scale, enabling the operator to select any one of a number of edges. Selection of the desired edge is simple: click the appropriate buttons in the edge selection menu and adjust a threshold level using the mouse.

Gray scale processing

Dust clearly removed by the projection probe

Edge selection graphic window

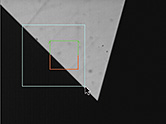

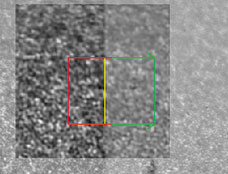

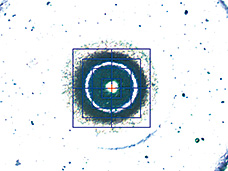

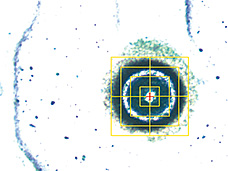

Enhanced edge detection with Nikon's unique algorithm

Thanks to Nikon's proprietary edge detection algorithm (patent pending), detection of edges at low magnifications is now possible with excellent precision. This enables the detection of minute, low-contrast edges, a task that is difficult to perform using gray scale processing. Image recognition capability almost equal to the human eye and a detection speed among the world's fastest allow the system to measure any workpiece with unrivaled precision.

Only a main edge is extracted and enhanced

Processing window

Before edge enhancement

Processing window

Enhancement after eliminating noise factors

Processing window

Advanced intelligent search

Skew alignment and deviations between the edge probing points within a workpiece are automatically corrected by a pattern-matching feature, eliminating possible measurement errors.

APS (Auto Position Search)

Thanks to this function, the operator no longer needs to manually place multiple workpieces in proper alignment; the NEXIV automatically searches workpiece position for skew alignment.

Search on left-side mark

Search on right-side mark

Before APS

After APS

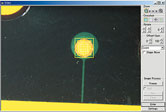

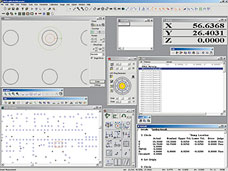

MPS (Multi-Pattern Search)

Automatically corrects deviations between the edge probing points programmed in a teaching file as well as irregular feature positions without edge probing error.

Normal pin location

Pattern matched on abnormal pin location

Circle probe appears on the abnormal pin location without measurement failure

PMM (Pattern Matching Measurement)

Determines coordinate values for features too difficult to measure in the normal geometric measuring mode.

Trained pattern 1

Actual searched pattern 1

Actual searched pattern 2

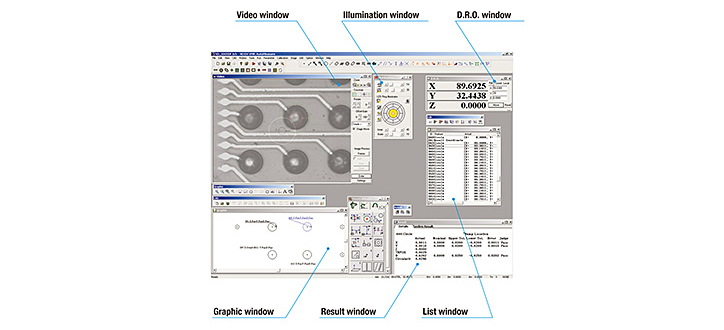

User-friendly standard software: VMR AutoMeasure

Main program

Interactive teaching wizards

Teaching wizards

A set of default teaching wizards provides step-by-step guides to facilitate teaching, regardless of the knowledge or experience of the operator. Besides these, operators can customize teaching wizards by registering frequently used teaching procedures.

Interactive measurement wizards

Measurement wizards

The measurement wizards guide operators, step by step, through what is required to achieve their tasks. In addition to the default wizards, operators can create customized wizards by registering frequently used procedures to streamline future operation.

Online CAD interface program

CAD graphic window

By importing CAD data (IGES, DXF, Gerber, and Excellon) of a workpiece, the operator can display its graphics in the CAD graphic window on NEXIV VMR AutoMeasure. This facilitates efficiency in teaching and shortens working time.

- The operator can move the stage to the desired position by double-clicking the appropriate position within the input workpiece.

- This function makes it possible to create a teaching file automatically from CAD feature data on NEXIV VMR AutoMeasure.

CAD interface off-line teaching support program: NEXIV Virtual AutoMeasure

This program enables CAD data to be read into the Virtual Video Window on a separate computer, allowing the operator to use NEXIV's teaching program with the same operational procedures as on the online computer. This eliminates the necessity of using the actual workpiece during teaching sessions and lets the NEXIV system concentrate on automatic measurement for increased productivity.

- Supports IGES, DXF, DMIS, NC files, Gerber, and Excellon.

- The Virtual Video Window enables the operator to confirm the current field of view based on CAD data.

- Same operational procedures as the NEXIV AutoMeasure.

- Manual or one-click automated programming.

- Possible to combine programs with Macro steps, such as Line Width Measure and Multi Pattern Search.

Two-dimensional profile shape analysis program: NEXIV Profiler

This program makes it possible to measure and judge 2-dimensional profile shapes in a workpiece that cannot be measured in the normal geometric mode. Now more accurate quantitative measurements can be taken than with the chart comparison method using profile projectors and/or conventional measuring microscopes.

Shape profile function

The NEXIV can now accomplish the following measurements. When the operator enters the start point, end point, and the measurement pitch, NEXIV automatically performs measurement and saves the results.

On XY plane:

- Constant pitch profiling–along axis

- Constant pitch profiling–along vector

- Constant pitch profiling–along angle

On XZ/YZ plane:

- Height constant pitch profiling–along axis

- Height constant pitch profiling–along angle

Shape evaluation function

Deviations between the measurement results and the nominal shape data are graphically displayed on the monitor or printed out for easy evaluation.

- Calculation of shape deviations: axis direction; normal direction

- Table listing of shape data

- Graph drawing of shape data

- Creation of nominal shape data: data can be created not only by keyed-in entry but also from CAD data. Data creation by exchanging the measured shape data is also possible.

Shape "best fit" function

This function is used to minimize the deviation between the measurement results and the nominal shape data. Deviation evaluation is easy even when the two use different coordinates.

Creation of nominal shape data from CAD data

Nominal shape data can be created from CAD data in the DXF/IGES file format.

Constant pitch profiling on XY plane

Height constant pitch profiling on XZ plane (IC lead)

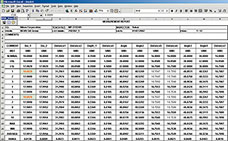

Report generating program: VMR Report Generator

This software is fully compatible with the NEXIV VMR AutoMeasure software and enables the quick generation of inspection results sheets in various report forms including user-designed forms. Users can even customize the program for their own easier use by making macro scripts.

Operating environment: Windows® Excel2000/XP

Memory space: 64MB or more

An example of macro scripts written by users: In order to input manually the data measured by other instruments and compile them into one complete report, the macro automatically makes cell blanks and display them in sky blue and a message prompts manual inputs.

NEXIV VMR Control Program

This program enables multiple teaching files to be run sequentially according to set replay instructions.

- Simplifies the process of giving instructions to measure many different workpieces continuously, e.g., measurements of various dedicated jigs

- Allows the inspector's operating environment to be separated from that of the system administrator

- Enables the administration of inspection date, inspector, date of manufacture, lot number and other inspection data

- Automatic printing linked to inspection sheets