Options

Handy options save time and labor during the work process

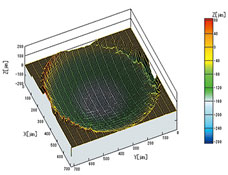

3D surface analysis program: NEXIV Bird's-Eye View

Running on Microcal Origin™, this program allows data obtained using the Scan Measure feature provided with TTL Laser AF to be plotted in a 3-dimensional format. After that, 3-dimensional shape analysis and 2-dimensional cross-section shape analysis can be performed.

- [Note] Microcal Origin™ is software developed by OriginLab® Corporation.

Surface analysis software: D-SURF

This software not only draws 3D graphics of a minuscule workpiece surface measured by the NEXIV system, but it also provides various analyses such as the calculation of various evaluation values.

Gear evaluation software

This software provides evaluations on various parameters of the measured workpiece, including pitch deviations, tooth space runout, base tangent length, and dimension overpin, based on industrial standards.

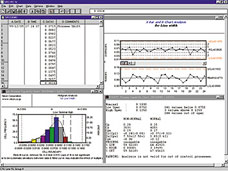

Real-time SPC via DDE (Dynamic Data Exchange)

Using a DDE Link function, measured data can be immediately transferred to spreadsheets such as Microsoft Excel®, SPC-PC IV, SPC-PC IV Excel, and others, making real-time SPC analysis possible.

- [Note] SPC-PC IV and SPC-PC IV Excel are products of Quality America Inc.

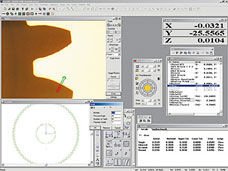

Lead frame AutoCAD-based teaching program: Measuring CADNF Super

This program creates teaching data using CAD design data. With excellent data compatibility and coordination capabilities between different data, this program promotes streamlined inspection.

- Supports commands necessary to measure lead frames, lead width, lead angle, and so on.

- Eliminates manual input work, allowing automatic measurements to be started immediately after components are delivered.

- Because CAD data can be checked during the preparation of teaching data, trouble in measuring product dimensions can be detected beforehand.

- [Note] This software is a product of Pronics Co., Ltd. To use Measuring CADNF Super, AutoCAD R14 is required.

Rotary indexer RI-3600L

The RI-3600L can rotate the image of a workpiece and display it with a 0.01° resolution. Because it can be controlled externally, it enables automatic measurements while controlling the posture of the workpiece.

Minimum readout: 1"

Control resolution: 0.01°

Max. workpiece diameter: 75mm

Operation mode: Auto or Manual

Pre-set points: Point of origin and 3 others

Dedicated isolation table

This pneumatic-type isolation table effectively absorbs external vibrations preventing them from affecting measurements.