Nikon Measuring Instruments User Case Study — 4 — FEITI PRECISION (THAILAND) CO., LTD.

Today we bring you the fourth installment in a series of reports on visits we are making to various manufacturing sites that use Nikon measuring instruments to manage product quality. This time we report on our visit to FEITI PRECISION (THAILAND) CO., LTD., where our interview took place on February 3, 2010.

Responding to a wide variety of manufacturing requirements from injection forming and pressing to assembly

FEITI PRECISION (THAILAND) CO., LTD.*1 was established in 2005 as the third plant in the Asian region of the Taiwan Fight Enterprise Co., Ltd. Group (Head office: Taipei), which as founded in 1968. The first plant, FEITI (Malaysia) SDN BHD, was established in 1995, and the second plant, FEITI (Thailand) Co., Ltd., a metal pressing plant, was established in 1998. FEITI PRECISION, located in the Rojana Industrial Park in Ayutthaya, Thailand, has been continuing to grow as a manufacturer and assembler of precision parts, and now has 400 employees and a production line of 80 injection molding machines.

Mr. Yasunari Ueda, factory manager of quality assurance, commented: "We aim to become a tridimensional company, responding to diverse customer needs with higher-quality products at lower prices. 'Tridimensional' has two meanings: one reflects the three ways we respond to customer needs through injection molding, pressing, and assembly; and the other represents the three Asian locations we have, in Taiwan, Malaysia, and Thailand, meeting customer manufacturing needs around Asia." While Mr. Ueda guided us around the plant, we asked him how his plant used measuring instruments to manage quality.

- *1FEITI PRECISION (THAILAND) CO., LTD..

[Head office] 1/92 Moo 5 Rojana Industrial Park Tambol Kanham Amphur U-Thai, Ayutthaya 13210, Thailand

[Board of Directors] President, Lin Hui Chiu, Director, Lin Shih Chien, Managing Director, Yoshihisa Uchiyama

Optical parts injection molding and assembly line inside a clean room

In 2009, FEITI PRECISION expanded its clean room floor space to meet customer needs for forming optical parts. The company installed injection molding machines and inspection devices, and now ships optical parts to customers in Thailand.

The injection molding line and assembly line in the clean room started operations in 2009. Each part that is formed in the clean room is visually inspected and packaged.

Optical parts assembly line in the clean room

Focal length measuring unit (manufactured by Pearl Optical Industry Co., Ltd.) for optical lenses

Global expansion of production and measuring technology at the FEITI Group: Sharing the iNEXIV measurement teaching program among sites

Managing Director Uchiyama: "Our aim in installing the CNC video measuring system iNEXIV was to launch on-time production following acceptance of molds at the Taiwan and Thailand plants and to improve measurement data correlation between the two plants."

One iNEXIV was installed in Taiwan and two were installed in Thailand–one on the injection line and the other on the pressing line–making a total of 3 units. While the mold is being set up at the Taiwan plant, it creates a measurement teaching program and provides FEITI PRECISION (THAILAND) with the mold and measurement program. By using the same measurement teaching programs at the Thailand plant, FEITI PRECISION is able to shorten the measurement inspection process following mold acceptance and obtain high reproducibility of measurement data.

Mr. Ueda adds: "Since both plants use an iNEXIV to measure, we achieve greater data correlation concerning assembly parts and insert-molded parts that are distributed between the two plants."

An iNEXIV in operation at Taiwan Fight Enterprise

An iNEXIV in operation at FEITI PRECISION THAILAND

- Teaching data for an iNEXIV to measure parts came with the mold that was set up in Taiwan, and in Thailand it is possible to perform measurement inspections with the iNEXIV simultaneously with the start of parts production.

Injection molding line measurement technology (1)

Using multiple sensors for 3D injection-molded parts

Taking measurements using a Renishaw TP20 touch trigger probe with a star stylus attached to it. During teaching, points to be measured are easier to check by turning on the LED ring illumination.

Mr. Ueda continues: "Some of the molded parts which FEITI accepts are relatively large 3D parts that are black. After considering measurement requirements from the standpoint of the need for wide-angle viewing and the fact that measurements cannot be taken from images, we decided to attach a touch probe to the CNC video measuring system iNEXIV VMA-2520. We need to measure inside cylindrical shapes, and the star stylus is an indispensable tool."

Injection molding line measurement technology (2)

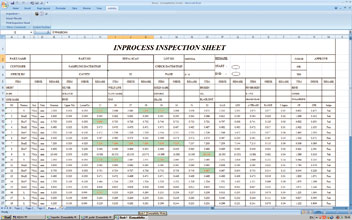

VMR Report Generator: Automatic generation of multiple cavity measurement reports

Though continuous measurements of one teaching file must be taken when measuring the parts of multiple cavities, one of the steps in the measuring process that takes time is the generation of reports on measurement data. Since FEITI PRECISION attaches electronic data when they deliver products to customers, the data must be easy for customers to read. In the past, the data was normally written by hand onto a standard format, but when FEITI PRECISION adopted the iNEXIV, they started using a report generation program. Since VMR Report Generator can also customize forms based on Excel, the company can now save considerable time between continuous automatic measurement and report generation.

- VMR Report Generator generates a measurement report simultaneously with the completion of measurement by the iNEXIV. It runs as an Excel VBA macro and automatically reads measurement data, ascertains tolerances, tabulates statistics, and generates the report.

Injection molding line measurement technology (3)

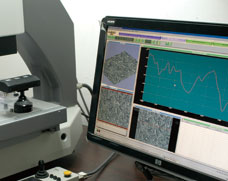

EDF/Stitching Express: Obtaining 3D data with wide fields of view

EDF (Extended Depth of Focus) from a highly enlarged image. Focal point synthesis images are used to inspect texturing transferred to a molded part surface.

When making 3D injection-molded parts, if the rate of enlargement is increased to obtain high-definition images, the depth of focus becomes shallower. As a result, the required image data is actually more difficult to view at times. Mr. Ueda describes their solution: "We use EDF/Stitching Express to import 3D images in high-definition and attach them to the inspection report. We use the iNEXIV as a retrieval device to import images such as overall images of samples and textured images of molded part surfaces."

Taking measurements on a sequential press molding line: Continuous automatic measurements using the APS function

Teaching the positions of multiple samples lined up on the stage. The automatic continuous measurement program using the APS function can be executed by simply designating the approximate start position.

Since many parts measured on a press molding line are relatively flat, FEITI PRECISION has adopted an iNEXIV with an image processing sensor and laser AF. Multiple samples need to be continuously and automatically measured no matter what size they are, so FEITI PRECISION takes sufficient advantage of the iNEXIV's functions to perform measurements automatically.

With the iNEXIV's APS (Auto Position Search) function, automatic measurement is possible simply by lining up the samples on the stage so that they basically face the same direction and designating the measurement start point for each sample.

Wish list for Nikon measuring instruments: Support for 3D model data

To respond to the manufacturing needs of various kinds of customers, the Taiwan Fight Enterprise Co., Ltd., Group receives drawing data as 3D CAD models from customers and utilizes them for designing and manufacturing the molds. For the future, however, Mr. Ueda says: "In the inspection process, most instructions continue to come as 2D drawings, so we plan to build a measurement process that effectively takes advantage of digital data."

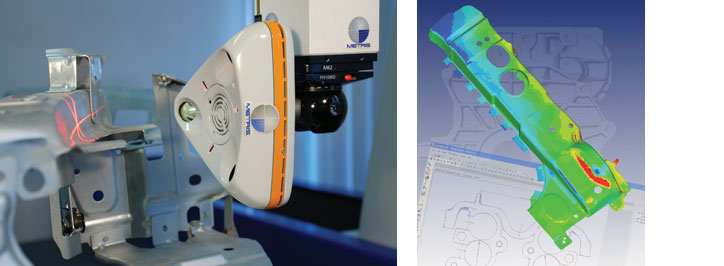

In October 2009, Nikon added Nikon Metrology NV (head office in Belgium) to the Nikon Group as a core for the contactless 3D sensor development and marketing business, making it more possible now to develop proposals for expanding the streamlined production system and incorporating measurement inspection processes that utilize 3D digital data. Along with further enhancing the functionality and precision of contactless 3D sensors, Nikon would also like to develop products that utilize 3D digital data in image measurements.

(Photos and text: Shuichi Sakai, Industrial Instruments Section, Sales Strategy Department, Sales Division, Nikon Instruments Company)

- XC65D Non-Contact Cross laser 3D scanner and Focus Inspection software, made by Nikon Metrology NV. Surface point data can be imported and compared with 3D model data for errors.