Great success derived from difficulties.

Although I am an optimist, a worrying situation even woke me up in the middle of the night.

Please tell us about the most unforgettable event in your career.

It was when we developed a thin film for an optical system loaded on a satellite during the 1990s. Our expertise cultivated throughout the years became useless when developing thin films to be used aboard a satellite in vacuum. Conventionally, we had employed vacuum deposition, in which a thin film is formed on a glass surface in a vacuum with deposits evaporated from metal and oxidized materials. The thin film formed in this method absorbs moisture in the air, which increases the refractive index of the film. We manufacture a thin film to be used in air based on this refractive index. But when the film is exposed to a vacuum environment, where the moisture in the film is desorbed, the refractive index deteriorates. That means, the film absorbs moisture during performance measurement after it is formed, but this moisture is adsorbed when the film is put to use in a vacuum. With this premise, we had to develop a thin film with the necessary refractive index and certain functions.

How challenging was the process of development for you?

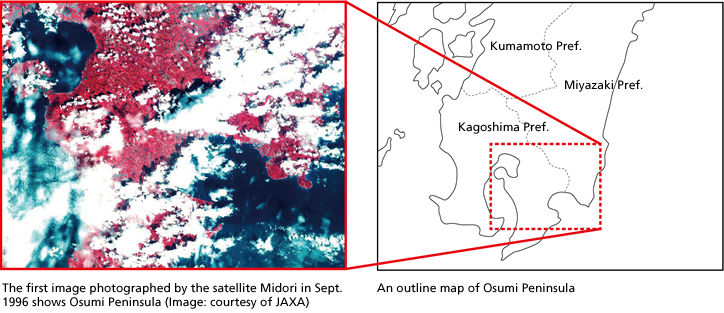

The process of development, which began with choosing the right material, was extremely difficult. We repeated experiments again and again, and had meetings over the results everyday to determine our next step. This continued for months. As a result, we succeeded in completing a design of the film that would not change its properties regardless of whether it is used in air or in vacuum. The advanced Earth observing satellite, Midori (ADEOS), loaded with the optical system that employed our thin film was launched successfully in 1996. We were really elated when we saw the photos of Osumi Peninsula in southern Kagoshima prefecture, taken by this optical system.

This project reminded us of the lesson we learned that we must confirm everything with the data before making any next move and never start anything only with assumptions. I am a born optimist, but at this time, this project stressed me out and used to wake me up in the middle of the night. This project had Japan's pride, let alone Nikon's pride at stake.

The importance of Chemical Clean technology emerged.

How would you evaluate this development of a thin film for a satellite?

The experience was very fruitful. That experience became particularly valuable as we continued the challenge of improving film quality corresponding to the ever-shorter wavelength of light sources for IC steppers and scanners. When searching for an evaluating method of an optical thin film developed for krypton fluoride laser light, we noticed that exposing ultraviolet light on an evaluation substrate increases the substrate's transmittance. It was because the ultraviolet light dissolved and eliminated organic substances sticking to the substrate surface.

Were these organic substances affecting the transmittance?

While they have no influence on ordinary light including visible light, they change the transmittance of light of an extremely short wavelength. In fact, the influence was barely noticeable when the substrate was used with krypton fluoride, but it was strongly apparent with argon fluoride. I had a hard time convincing the optical designer and others that organic substances could affect the transmittance even when used with krypton fluoride.

What is the true identity of these organic substances?

They are derived from various sources; hand stains, the breath and perspiration of humans; cutting oil remaining on metallic components; surface coating materials; cable jackets of wiring and connector plastics; construction materials of the facilities; and various resins. Clean rooms, no matter how stringently maintained, are full of contaminant sources. Conventional clean room technology has targeted dust and particles in the size range of 0.5 to 1μm. Organic substances in the air, on the other hand, are much smaller and at the same level as gas molecules. The technology to eliminate these organic substances, we call Chemical Clean.

How did the demand for Chemical Clean technology arise?

As the number of IC steppers and scanners with argon fluoride light source increased, the importance of Chemical Clean technology became widely recognized. I continued on to develop technologies that would eliminate organic substances from optical parts surfaces and that would maintain the cleanliness. Later, a group devoted solely to Chemical Clean technology was formed. This group explored various technologies such as removing organic substances from the spot where the light source hits or eliminating the cause of such substances.