Polishing the test plates for a cylindrical lens

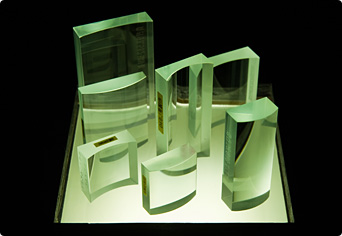

Cylindrical lens test plates—a diversity of sizes and curvatures

Polishing a cylindrical lens using a special polishing machine. A pitch known as bitumen, a distilled petroleum product, is applied to the polishing plate as the polishing material.

Test plates are made of glass that represent the standard shape and curvature of a lens. Since it serves as a standard, it must be polished to an even higher degree of precision than ordinary lenses are. Mr. Kudo is in charge of polishing test plates for cylindrical lenses (lenses with a curved surface and a flat surface), which are used in the illumination systems of IC steppers and scanners.

Ordinary lenses are polished into a rounded shape using a rotational oscillating motion for polishing. For a cylindrical lens test plate, however, the shape is attained using a special polishing machine, in which the lens is polished using a linear motion, with the polishing plate and glass orthogonal to one another.

Within the Nikon group, there are any number of factories at which polishing is carried out. Due to the high degree of skill required, however, there are only a handful of technicians (Mr. Kudo among them) who can polish cylindrical lens test plates properly.