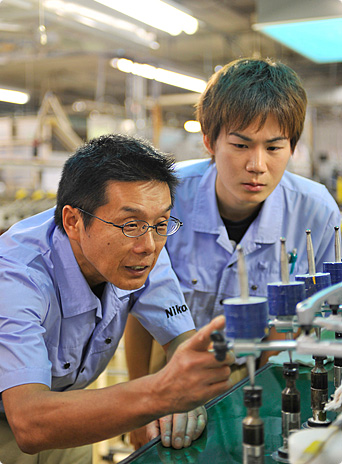

Passing on real-life techniques

Mr. Okawa teaching a young technician

"I just didn't think I would be able to do it" says Mr. Okawa, in reference to the manufacture of a test plate for use in interferometers for inspecting the projection lenses in IC steppers and scanners.

Just like a lens, a test plate is made by grinding and polishing glass. However, this test plate was to have a degree of precision and an order of magnitude higher than that of a lens. Mr. Okawa was in charge of its production in 1997. At that time there were no high-precision measurement machines up to the task at the factory where polishing was performed. Hence, the production process was carried out in cooperation with a specialist measurement unit, with polishing and measurement of the test plate being repeated many times, and it took more than three months to complete its manufacture.

"You cannot learn a technique simply by reading a manual, since there is a sensory dimension to technique that the manual does not convey. To impart this sensory dimension to trainees, I teach them the important points as I work with them, and do my best to enable them to acquire real-life techniques. On top of all this, by succeeding at difficult tasks that had seemed impossible, we improve our technique."

To an optical instrument manufacturer like Nikon, lens-polishing is an indispensable technique, and each generation of technicians successively passes it down to the next. Embodied by these technicians, it is a technique that continues to live on.