The lens-polishing process

1.The polishing plate is heated on a gas stove and resin is placed on the plate to soften.

2.The polishing plate is pushed down onto the polish-forming plate to form the resin into the reverse shape of the lens surface.

3.A blade is used to trim the excess resin off the polishing plate.

4.A knife is used to cut correction grooves into the resin to adjust the amount of friction between the lens and the polishing plate.

5.The lens is secured in place on the polishing machine and a polishing liquid is applied to the surface of the lens using a brush.

6.The polishing plate is placed on the polishing machine and rotated. This commences the polishing.

7.The polishing plate's contact surface is adjusted by cutting correction grooves in accordance with the levels of polishing.

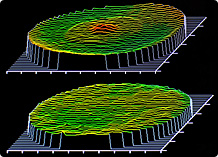

8.The surface of the lens is measured using an interferometer to verify the level of precision. This completes the polishing process. Image shows the surface of the lens: before polishing (above) and after polishing (below).