XT V 160 Electronics X-ray Inspection

Top-class inspection system for miniaturized electronic components

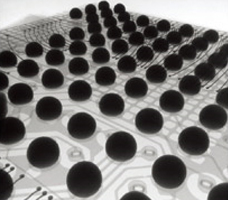

Component connections on today’s compact and densely populated PCBs are hidden by other components, making X-ray the only viable inspection solution. XT V 160 is an easy-to-use, cost-effective and high-quality PCB inspection system targeting production facilities and failure analysis laboratories.

In automated inspection mode, samples can be inspected at the highest throughput. In manual mode, intuitive software and high-precision sample manipulation enable operators to visualize and evaluate the tiniest internal defects and deficiencies.

Features

- NanoTechTM source with submicron focal spot size

- Fast data capture and high-quality imaging

- Large tray for loading multiple boards

- Customizable macros automate measurement workflow

- Remote validation station available

Applications

- Solder reflow analysis

- BGA connectivity and analysis

- Solder void calculation

- Through hole measurement and inspection

- Die attach voiding measurement

- Ball bond analysis

- Stitch bond analysis

- Micro BGA / chip on chop analysis

- Pad array analysis

- Dry joint detection and analysis

Benefits

- Flexibility combined in one system

- Interactive visualization

- Fully automatic X-ray inspection

- Optional CT for in-depth analysis

- Fast operation with intuitive GUI and interactive joystick navigation

- Low-cost maintenance with open-tube technology

- Safe system requiring no special precautions or badges

- Small footprint