XT V 130 Electronics X-ray Inspection

Compact, versatile and easy-to-use electronics QA system

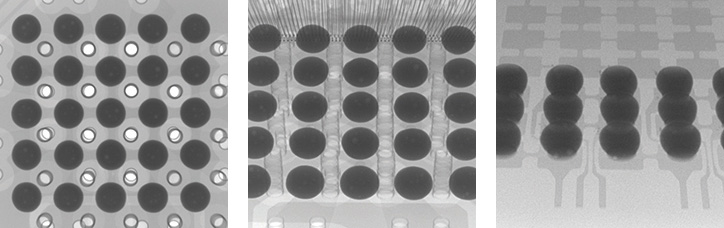

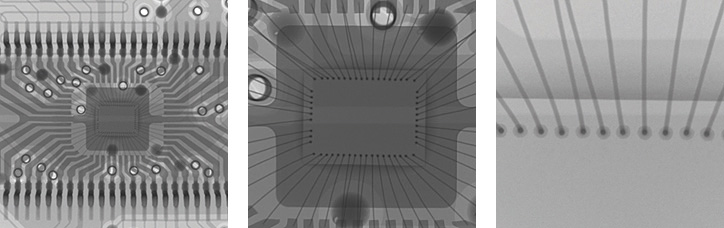

With the advent of many newer type of electronic components, surface inspection is no longer an option. As most electrical connections remain hidden for the eye, the ability to run premium quality real-time X-ray is more important than ever before. Designed for 100% (μ)BGA, multi-layer and PCB solder joint inspection, the XT V 130 X-ray system is a high-precision, flexible solution that facilitates defect analysis in loaded PCB boards. The system's Inspect-X software offers automated inspection functions and (optional) automatic board identification, which ensure high inspection throughput rates.

Up to 320x image magnification enables users to zoom in on any specific item of interest

Features

- Proprietary micro-focus source with 3 micron focal spot size

- High, 16-bit resolution imaging and image processing tools

- Large tray for loading multiple boards

- Optional rotation table (360° continuous)

Applications

- Electronic and electrical components

- Broken wedge bonds, lifted ball bonds, wire sweep, die attach, dry joints, bridging/shorts, voiding, BGA, etc.

- Populated and unpopulated PCBs

- View surface mount defects i.e. misaligned devices, solder joint porosity and bridging

- Detailed inspection of vias, through-hole plating and multi-layer alignment

- Wafer-level chip scale packages (WLCSP)

- BGA and CSP inspection

- Non-lead solder inspection

- Micro-electro-mechanical systems (MEMS, MOEMS)

- Cables, harnesses, plastics and many more

Benefits

- X-ray inspection workhorse for electronics quality assurance

- Macro-based automation requires no programming skills

- Component-specific automated pass/fail analysis, off-line visualization station and automatic report generation

- Ready to automate complex tasks with VBA

- On-line operation with intuitive joystick navigation

- Low-cost maintenance with open-tube technology

- Safe system requiring no special precautions or batches

- Small footprint and low-weight for easy installation