Laser Radar MV330/350

Automated, non-contact large volume inspection

Laser Radar is a versatile metrology system that offers non-contact and true single-operator inspection. As it is CNC-programmable, it is ready for completely automated unattended operation. Laser Radar incorporates patented laser reflection technology that allows for direct surface and feature measurement at high data rates. As a result, Laser Radar eliminates the tedious use of photogrammetry dots, spherically mounted retroreflectors (SMRs) or handheld probes, slashing inspection time and operator overhead. Laser Radar is able to scan dark diffuse and highly reflective material and finish surfaces at challenging incident angles.

Features

- Measurement range for MV350 up to 50m, MV330 up to 30m

- Vision Scan inspection mode captures up to 2000 points per second

- Accuracy from 24µm (2m distance) to 201µm (20m distance)

- Powerful hole and edge measurement capabilities

- Expanded line of sight using mirrors

- All acquired data referenced to a single contiguous coordinate system

- Supports a variety of large volume metrology software

Benefits

- Productivity multiplier thanks to fast measurement and low operator overhead

- Non-contact measurement ideal for delicate and inaccessible specimens

- Automation saves on operator expenses and manipulation errors

- Reliable range measurements on composite materials

- Seamless integration in measurement process

Applications

- Inspection of fuselage, wing, wing/body connection, landing gear door and jet engine blade

- Gap and step inspection of jet engine cowling

- Automated inspection of riveting hole positions

- Mold, first article and serial inspection of composite parts

- On-machine verification of large machined parts

- Dimensional verification of forged and molded parts before milling process starts

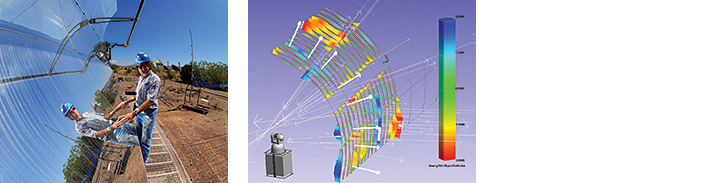

- Measuring wind turbine blades and concentrated solar panels

- Verification of space telescope hardware, parabolic antenna and heated surface