LC60Dx/LC50Cx/LC15 Line Scanners

Digital laser scanning boosts inspection performance

The all-digital LC60Dx brings laser scanner in the accuracy range of tactile measurement, while offering the advantage of capturing a multitude of measurement points. Equipped with state-of-the-art CMOS technology and powerful on-board data processing, the LC60Dx scanner more than triples today's common scan rates. This enables manufacturers to drastically reduce the inspection cycle time for freeform parts, or boost the number of features that can be scanned in the same time frame.

The LC50Cx laser scanner offers an adequate productivity with its 50mm stripe width and scanning rate of 45 stripes per second. And LC15, with its smaller field of view perfectly suits digitizing small or detailed objects with higher point density and tighter tolerances.

To effectively scan surfaces with varying color or high reflectivity, LC60Dx and LC50Cx provide automatic real-time adjustment of sensor settings for each individual point of the laser stripe.

Features

- Laser stripe width of 60mm (LC60Dx), 50mm (LC50Cx) or 15mm (LC15)

- Accuracy of 9µm (LC60Dx), 19µm (LC50Cx) and 4mµ (LC15) in multi-stylus test comparable to EN/ISO 10360-5 MPEAL

- Enhanced Sensor Performance (ESP3) incorporates dynamic point-per-point adaptation of laser source intensity.

- Scanning rate 75,000 (37,500) points/sec for LC60Dx (LC50Cx)

- Fully compatible with Renishaw PH10M(Q) and automatic change racks (ACR3)

- Data collection over multi-wire is integrated into most CMM brands and types

- Designed for minimum warm-up time and maximum operational stability and robustness

LC60Dx

LC50Cx

Applications

- Inspection and reverse engineering of mobile phones, turbine blades, tools, castings, dies, sheet metal parts, plastics, etc.

| LC15Dx | LC60Dx | LC50Cx | |

|---|---|---|---|

| Field of View | 18x15mm | 60x60mm | 50x60mm |

| Probing error (MPEp)1 | 2.5μm | 9μm | 20μm |

| Data acquisition (approx. pts/sec) | 70,000 | 77,000 | 37,500 |

| Enhanced scanner performance (ESP3) |

√ | √ | √ |

- Nikon Metrology test comparable to EN/ISO 10360-2

LC15Dx is suited for inspection of complex parts with tight tolerances, e.g. medical implants, turbine blades and precision moldings.

Related solutions

- Bridge, horizontal arm and gantry CMMs

- Focus point cloud software, Inspection and Reverse Engineering software

- Camio multi-sensor CMM software

-

BENEFITS OF CMM-BASED LASER SCANNING

- Simplified measurement and processing setup

- Teach scan paths or indicate scan area on CAD

- Import feature properties and GD&T information directly from CAD

- Macro functionality for fully automated scanning and inspection

- Reduced measurement time

- Reduction of probe head movements

- XC65D(-LS) scanner captures full feature information in a single movement

- Unique capability to measure freeform and fragile surfaces

- Detailed description of freeform surface in short time interval

- Non-contact measurement eliminates the need to touch fragile and delicate parts

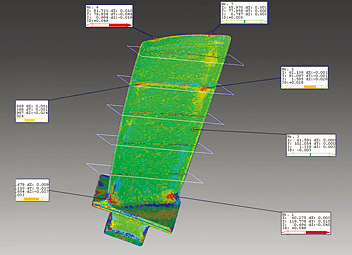

- Powerful reporting with colored CAD deviation maps

- Input for reverse engineering, rapid prototyping, finite element calculations, and digital archiving

- Simplified measurement and processing setup