My explorations of optics and metrology continue

Participating in a national project and meeting expectations.

You were involved in the development of important technology, soon after you joined the company, we hear.

I participated in the development of test equipment for the projection lenses used by IC steppers and scanners. Four team members, who are my experienced senior colleagues and I, decided the basic specifications.

Please teach us about projection lenses for IC steppers and scanners.

IC steppers and scanners etch nanometer-sized IC circuit patterns on wafers by exposing them to the light projected through a huge lens comprised of multiple lenses. By passing light through this combination of lenses that is designed based on meticulous calculation, the light converges at one point and achieves high resolving capability. This requires full utilization of the performance of short-wavelength light, which is very difficult for us to realize.

We also need to examine if these high-precision projection lenses can perform to their specifications, which requires another complex technology.

So, what device did you invent?

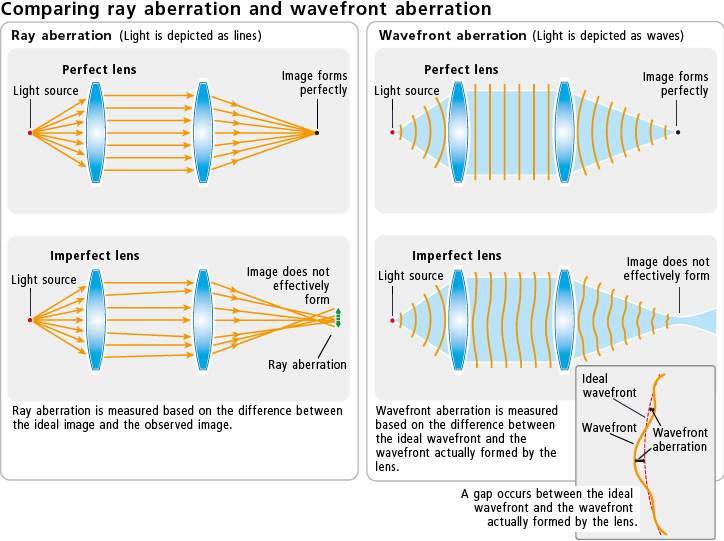

Conventional projection-lens test devices evaluate lens performance by measuring the behavior of ray aberration of the lens. This kind of equipment measures the degree of aberration from the shape of an optical image. Measurement is quite simple, as the collection of optical rays appears as an optical image, which allows you to intuitively understand. But you cannot locate malfunctions based on such optical images. We developed test equipment based on wavefront aberration measurement. Measuring wavefront aberration provides more information than optical images, so that we can specify the exact component that is causing problems. Wavefront aberration measurement had been recognized as a way to evaluate the profile of a lens or mirror surface previously, but it had never been employed in the inspection process of IC steppers and scanners.

Our development project was somewhat delayed and so was the device's implementation. But the technology we developed at that time forms the basis of all test equipment that followed.

After that, you took part in a national project?

That's right. I joined the Hirohashi Cell-Configuration Project, one of the ERATO* projects, as a researcher around 1995, developing the world's first laser-scanning optical CT microscope at an institution in Tsukuba, Ibaraki Prefecture. The laser CT microscope whose development I had been involved with during my graduate study obtained a series of two-dimensional images in one operation employing a CCD camera. Projection control, that is necessary for CT processing, was performed by the illumination system. On the other hand, this new microscope, taking advantage of scan imaging, is designed so that the projection of images can be changed during post-processing. Therefore it captures a pupil image.

Could you tell us more about it?

The Hirohashi Cell-Configuration Project was based on a theory proposed by Dr. Setsuo Hirohashi, who was Deputy Director of the National Cancer Center Research Institute at that time. The project, which aimed at detecting the initial signs of cells transforming into cancer and other disease cells, required three-dimensional observation of live cells. I was invited to develop a three-dimensional biological microscope. This provided me with an opportunity to spend much time working with researchers in medicine and biology, allowing me to also acquire broader perspective. The knowledge I gained back then gave me advantages for my later work at Nikon.

- *ERATO (Exploratory Research for Advanced Technology): This national project, led by the former Research Development Corporation of Japan (JRDC), began in 1981 to promote basic and innovative research in science and technology. Although the project was remodeled under the Japan Science and Technology Agency (JST) and is now renamed Strategic Basic Research Programs, the name "ERATO" is still often used.

Continuing research with the same theme produces outstanding results.

What did you do when you returned from ERATO?

I developed a new type of test device for projection lenses of IC steppers and scanners. It was based on a different measurement theory from that employed for the device I developed before my work at ERATO. Projection lenses, required to achieve maximum performance, are difficult not only to develop and design but also to manufacture. A projection lens cannot perform to specifications if even one lens in the combination is out of position by even a few micrometers.

The test device I developed at that time delivers the capability of analyzing which lens in the combination is causing a malfunction, while it can examine if the projection lens performs as intended. This equipment received a company award, as did its successor machine that I developed the next year.

What do you think was the key to such success?

I think I was able to contribute to raising the morale of the onsite manufacturing staff as well as increasing productivity. Problems occurring during the assembly of project lenses used to be solved by contacting the lens designer each time. But the designer cannot always be available. After installing the equipment I developed, more of such problems were able to be successfully handled by onsite staff. This increased productivity and contributed to more effective distribution of the lens designer's expertise and resources.

And what about raising morale among onsite staff?

Conventionally, the onsite staff had dealt with these kinds of issues only by following the instructions of the lens designer they contacted. They had not understood completely for themselves what had gone wrong or where an error had occurred during production. It was a passive task, which produced nothing that contributed to the staff's skill development. However, after installing the new device, they could effectively locate the cause and solve more problems by themselves. As they gained a better understanding of the equipment and products, their motivation also increased.

That is a great result.

I now realize that I have continuously pursued optics and metrology as my theme since I was in college. I believe that continuing research with a consistent theme leads to great results. Keeping the same theme until I feel completely satisfied with what can be achieved through it is my style and this will never change.