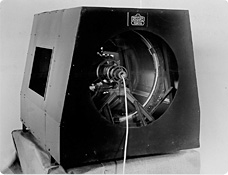

Television Projection Device No. 1

Television broadcasting in Japan began on February 1, 1953, with the first regular broadcast by the Japan Broadcasting Corporation (NHK). On August 28 that same year, Japan's first commercial TV station, Nippon Television Network (NTV), also commenced broadcasting. At the very dawn of TV broadcasting in Japan, Nikon (then known as Nippon Kogaku K. K.) was also involved in events.

The enlargement of TV screens

A crowd assembled around a public TV. Photographed in 1954.

Picture courtesy of the Mainichi Newspapers

Television sets were not in widespread use at the time, due to their extremely high cost. As a result, from 1953 to 1962, NTV installed public televisions in well frequented locations, such as department stores, railways stations and parks. Since the screens of these public TVs ranged in size from 17 to 27 inches, it would have been difficult for people at the back of a large assembled crowd to see the program being shown.

Thus, the need for larger screens arose, so as to enable viewing by greater numbers of people. Three approaches to enlarging TV screens were considered, as follows:

- To develop a larger screen that emits light to display images.

- To project the image onto a medium such as oil film or photographic film, and then project an enlarged version of the image onto the screen using a separate light source.

- To enlarge the image from the picture tube using a lens or mirror, and then project it onto a screen.

Nikon was engaged in the production of television projection devices that employed the third of these approaches, known as schemes.

The evolution of projection schemes

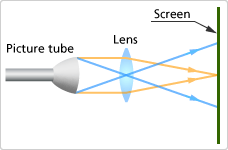

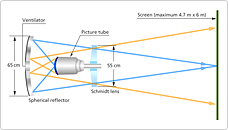

Fig. 1 shows the earliest type of device, which employed the scheme of using a lens to enlarge the image from the picture tube and project it onto the screen. This scheme requires a large-diameter lens in order to project a bright image onto the screen. There are major disadvantages to larger-diameter lenses, such as the occurrence of aberrations and the production techniques required.

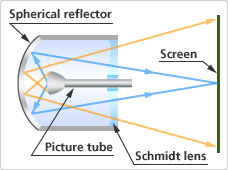

As a result, a scheme was considered in which the picture tube was covered with a spherical reflector that reflected the light from the picture tube. It proved impossible to obtain sharp images, however, as the spherical reflector produced spherical aberrations and coma aberrations. In order to correct those aberrations, a design incorporating a Schmidt lens (as shown in Fig. 2) was devised.

Fig. 1 Projection scheme using a lens

Fig. 2 Projection scheme using a Schmidt lens

The Schmidt lens

If the main mirror in a reflecting telescope is spherical, spherical aberration and coma aberration will occur and the observed image will be corrupted. The Schmidt lens is an aspherical lens that is designed to correct this problem. It was invented by the German Bernhard Schmidt in 1930 and is also known as the Schmidt corrector plate, since it was designed to correct aberrations.

Since the Schmidt lens is an aspherical lens, it is more difficult to manufacture than an ordinary spherical lens. During World War II, Nikon engaged in the experimental production of a small-diameter (20 cm) Schmidt lens. As late as the 1950s, however, the company was still finding it difficult to manufacture large-diameter Schmidt lenses.

By contrast, television projection devices that made use of large-diameter (around 50 cm) Schmidt lenses had already been tested in the United States during the 1940s. The latter half of the 1940s had even witnessed the release of large-screen household TVs whose projection schemes made use of the Schmidt lens.

The development of large-diameter Schmidt lenses

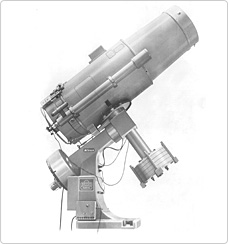

Television Projection Device No. 1 (with cover removed)

In July 1952, Nikon embarked on the development of a large-diameter Schmidt lens for installation in television projection devices. The basic optical design was completed by the end of the year. The development period had been scheduled to run until the end of March 1953. However, Television Projection Device No. 1 (hereafter Device No. 1) was not in fact completed until the end of December 1953.

The delay was due to the fact that, as with Nikon's first foray into the development of a large-diameter Schmidt lens, the project presented continuous difficulties. Various societal conditions also took their toll, such as a delay in the sell-off of state-owned vertical grinding machines that were required for precision machining, and electricity shortages due to a coal miners' strike that rendered work on the project impossible.

Focal length: 39 cm f/0.75

Diameter of spherical reflector: 65 cm

Diameter of Schmidt lens: 55 cm

A ventilator 10 cm in diameter was located in the spherical reflector that enabled cooling of the picture tube.

Device No. 1 incorporated a 55 cm large-diameter Schmidt lens. The picture tube used for the projection of images was a 7-inch tube manufactured in the United States. Even on a large 4.7 m x 6 m screen some 18 m away, the device was capable of fully resolving 525 scanning lines.

After the completion of Device No. 1 it became clear that the X-rays generated by the picture tube also had to be dealt with, and the development period was extended even more. With the addition of various improvements, such as the coating of metal components, Device No. 2 was completed by the end of March 1954.

The Universal Large Polishing Machine for Schmidt Lenses

A further objective in developing television projection devices was the successful manufacture of large-diameter Schmidt lenses, an area in which Japan lagged behind the West. To this end, Nikon pursued the development of a special-purpose polishing machine.

At the start of development, the plan was to modify the vertical grinding machines being sold off by the government into large profile grinding machines, and use them with existing grinding and polishing machines for large lenses. However, the decision was later taken to equip the large profile grinding machines with grinding and polishing capabilities. There were various reasons for this, including the prevention of damage to the product that might be caused by carrying it around during the polishing process, and the ease with which precision control could be achieved if the grinding and polishing operations were all carried out on a single machine. This enabled the grinding, polishing and final polishing processes to be carried out in an integrated fashion. Completed at the end of November 1953, the device was dubbed the "Universal Large Polishing Machine for Schmidt Lenses" and was described as "a machine unknown even in the annals of foreign literature, let alone in Japan." This machine enabled the production of spherical and aspherical lenses, as well as large-diameter (up to 1 m) Schmidt lenses.

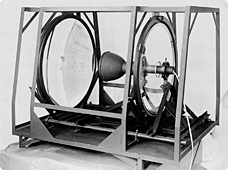

The unveiling of Television Projection Device No. 1, which took place on 14 January 1954 at the Industry Club of Japan

Actual images projected by Television Projection Device No. 1 at its unveiling

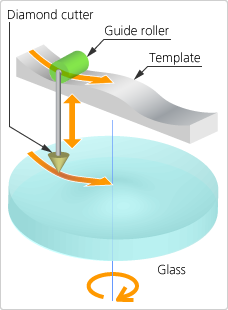

Profile grinding

In the grinding of aspherical lenses such as Schmidt lenses, the use of a precision-processing machine to first produce a template identical to the cross-sectional shape of the aspherical lens. As the glass is rotated, the template is used as a guide and the diamond cutter is moved radially to grind the glass.

Device manufactured using a large-diameter Schmidt lens

Once development of the television projection device had been completed, a prototype aimed at the commercial market was manufactured. However, the project did not meet with success, due in part to disadvantages such as the dark images that the prototype projected and its short projection distance.

Since it had now become possible to manufacture large-diameter Schmidt lenses, a few of these devices were successfully produced. A 50 cm diameter Schmidt lens was used in "the 50 cm comet astrograph" that Nikon supplied to the Tokyo Astronomical Observatory (the present-day National Astronomical Observatory of Japan) in 1964.

In 1968, Nikon introduced a numerically controlled (NC) aspherical grinding machine and pursued the development of lens-processing technology based on numerical control. In 1969, Nikon established its own unique aspherical profile processing machinery and precise aspherical processing techniques, achieving micrometer-level processing precision.

This processing machinery and these processing methods were used in the manufacture of a 105 cm Schmidt telescope installed in 1974 at the Kiso Observatory, the fifth branch observatory of the Tokyo Astronomical Observatory (now the Kiso Observatory operated by the Institute of Astronomy of the Graduate School of Science at the University of Tokyo). The Schmidt lens was 105 cm in diameter—the largest such lens that Nikon had ever manufactured, and the fourth largest in the world at the time.

50 cm comet astrograph

105 cm Schmidt telescope

Laying the foundations for aspherical-lens production

A television projection device of the day. A few devices were manufactured in around 1955 and then used for promotional purposes. These had a smaller diameter than Television Projection Device No. 1.

By engaging in the development of television projection devices, Nikon established the basis for production technology of large-diameter aspherical lenses, including Schmidt lenses. Making full use of these techniques, Nikon succeeded in manufacturing high-performance equipment for the observation of celestial objects that was equal to any such equipment the West had to offer.

Nikon has continued to develop aspherical lens production technology. As a result, aspherical lenses represent essential components in numerous Nikon products, including binoculars, microscopes, Ophthalmic Lenses and IC steppers and scanners. These lenses continue to demonstrate their effectiveness in improving the performance of optical systems.

Compiled with the cooperation of Nippon Television Network and the Nikon Former Employees Association