MCT225 for Metrology CT

MCT225 offering absolute accuracy for inside geometry

This new ‘absolute-accuracy’ Metrology-CT (MCT) system guarantees that all internal and external geometry is measured efficiently. A proprietary liquid cooled micro-focus reflection source and air-cooled cabinet provide long-term stability and enable the MCT225 to achieve an impressive accuracy specification. It offers superior measuring accuracy and small feature detection to inspect precision plastic parts, small castings and complex parts and assemblies.

Features

- Absolute accuracy 9 + L/50 μm in accordance with the VDI/VDE 2630

- Dual monitors for full-screen image and software controls

- Variable voltage 225kv micro-focus reflection source

- Easy-to-maintain open-type X-ray tube

- High-accuracy manipulator

- Protective enclosure reduces radiation exposure

- Sample size: up to 450 mm

- High-resolution 4-megapixel detector with 150x magnification

Applications

- Detailed analysis of the internal structure of turbine blades

- Automated pass/fail inspection of blades

- Inspection of high density parts (e.g. metal parts, castings) with a need for micron accuracy

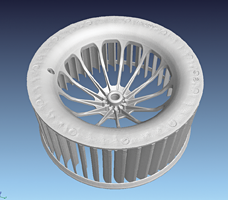

CT of plastic fan

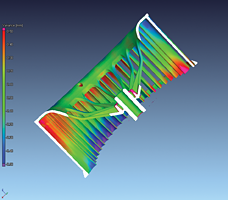

Part-to-CAD analysis

Voids in casting

Benefits

- Flexibility combined in a single system: X-ray for quick visual inspection, CT for in-depth analysis

- Fast data capture and high-quality images

- Fast operation with interactive joystick navigation

- High-resolution digital imaging and processing

- Safe system requiring no special precautions or badges

- Tight integration with industry standard post-processing applications