Nano Particle Coating

The light source used in state-of-the-art IC fabrication technology is the ArF excimer laser*1 with 193nm*2 wavelength. Nikon has developed a technology to form a coating with very low refractive index even in the vacuum UV (VUV, 200-150nm) region, and greatly improved the angular performance of antireflection coating. This ultra-low refractive index coating is called "Nano Particle Coating" because the size of the particles that compose this coating ranges from a few nanometers to just more than 10 nanometers.

To improve resolution of the projection lens, two methods are used: shortening the wavelength of the light source, and increasing the N.A. of the projection lens. When these methods are implemented, the requirements for the antireflection coating become harsher.

Generally, the shorter the wavelength is, the higher the refractive index is. The antireflection coating is a combination of coating with high refractive index and low refractive index, and the shorter wavelength causes deterioration of the angular performance of antireflection coating, because the performance depends on the refractive index of the low refractive index layer. In addition, most of the materials do not have enough transmittance in VUV region, so we have poor choice of available materials.

As for increasing the N.A. of the projection lens, in general, the larger the N.A. is, the larger the maximum incident angle of light into the lens is. The reduction of the refractive index of the low refractive index layer is very effective to prevent the reflection of light at large incident angles, therefore the development of such an ultra-low refractive index layer, as well as the aforementioned shortening of light source wavelengths, is of great importance.

Of the materials commonly known, the lowest refractive index at 193nm is 1.38. Nikon has succeeded in developing a coating with an ultra-low refractive index of 1.18 at 193nm, and the coating, which introduced the ultra-low refractive index layer, has the best angular performance in the world for ArF excimer laser.

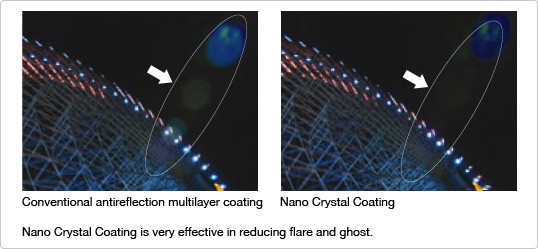

Nano Particle Coating is used not only in projection lenses in IC steppers and scanners, but is also in interchangeable camera lenses as a "Nano Crystal Coating". The technology achieves extremely high antireflection performance over a wide wavelength range, exceeding the levels of conventional antireflection coating. Moreover, its beneficial effect on flare and ghost induced by oblique incident light to the lens is unprecedented. It is currently employed in the AF-S NIKKOR 14-24mm f/2.8G ED, AF-S NIKKOR 24-70mm f/2.8G ED and other lenses.

- *1With a wavelength of 193nm, this type of laser is named after the inert gases used for discharge excitation: a mixture of argon (Ar) and fluorine (F) halogen.

- *2One billionth of a meter (10-9 meters).

Renewed March 2008