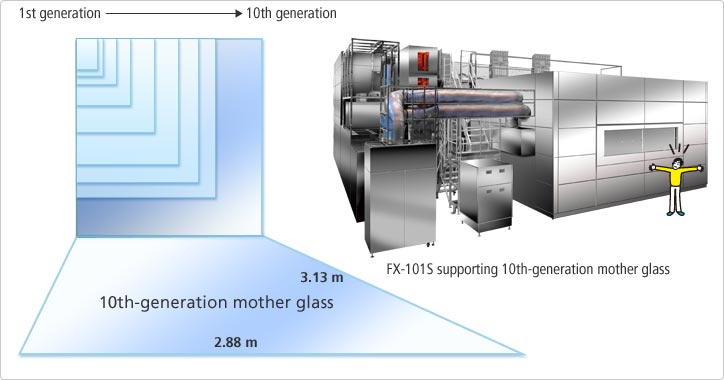

4. Supporting glass plates becoming ultra large

After one large glass plate, known as the mother glass, has been etched with circuits for multiple sheets of LCDs, the mother glass is then cut into individual LCD screens. The mother plate has recently evolved from the 8th generation to the 10th generation, and the size of the 10th-generation mother plate is as wide as 3.13 x 2.88 meters. Nikon supports this 10th-generation mother glass with the cutting-edge FX-101S, which was released in March 2009 and is capable of efficiently producing large-size panels of more than 60 inches.

To produce high-resolution and high-definition LCDs, the lens must accurately project the light beams as well as accurately measure and adjust for the plate position and warps in the plate itself. A variety of technologies are required, but Nikon has independently developed many technologies and applied them to its LCD steppers/scanners to achieve high productivity.