1. The role of encoders in industrial robots

Industrial robots are absolutely essential in the manufacturing processes of key industries.

Industrial robots, which carry out work beyond human ability, have today become an indispensable factor in manufacturing processes. In the field of factory production lines and machine tools, among other things, robots weld parts on the automobile production line, apply paint to parts of automobiles and household electric appliances without any unevenness at all, and transport wafers and other parts speedily and accurately. The joints of industrial robots are moved by the rotation of servomotors, and it is encoders that fulfill the role of measuring and controlling these movements. In addition, in recent years many autonomous robots other than industrial robots have appeared, and encoders are also active as control sensors for the servomotors used in the joints of humanoid robots that walk on two legs and pet robots. Numerous state-of-the-art technologies, such as optics, ultra-precision technology, and electronics, are condensed in these encoders.

2. Incremental type and absolute type

An encoder controls the motor in a 6-axis industrial robot.

There are two types of encoders for industrial robots: the incremental type*1 and the absolute type. The incremental type requires a return to the starting point (return to the original position) when starting up and when recovering after an emergency halt or power stoppage. The household inkjet printer offers an easy-to-understand example. When the power is turned on, such a printer needs to detect the position of the head and adjust it in order to restart. In contrast, the absolute type can detect an absolute position as soon as the power is turned on. The absolute type is therefore essential for processes in which serious problems would arise if the robot suddenly returned to the starting point. For example, if the power stopped on an automobile production line while a robot was painting the interior of an automobile, in the case of the absolute type, the robot would restart its movement at the point where it stopped. In the case of the incremental type, however, the robot would return to the starting line, which could damage the car and even cause collisions among robots.

- *1 Incremental type: Since this type of encoder uses information on cumulative rotations from the start, that information is reset if the system's power goes off and, when restarting, it is necessary to return each axis to its starting position.

3. High resolution realized by Nikon's technological strength

Nikon's absolute encoder has realized high resolution through the development of Nikon's original M sequence*2 pattern and reflective light-receiving sensor. The single-turn resolution of the absolute encoder is a maximum of 20 bits (2 to the power of 20: 1,048,576 counts/turn). As a result, this enables the precise determination of position and contributes enormously to enhancing the stability of speed control. In terms of the revolution of the Earth, taking the Earth's circumference roughly to be 40,000 km, the resolution would be 40,000 km ÷ 1,048,576 = 38.147 meters. In other words, vis-a-vis the circumference of the Earth, it would be possible to detect and control a revolving position with amazing accuracy in units of only 38 meters. As a result of the installation of this high-precision sensor for measurement and control, robot technology has taken a gigantic step forward.

- *2 M sequence: Short for maximal length sequence, this is formed by the irregular use of 0s and 1s, as in a barcode pattern. If this pattern is read in a longitudinal direction, during a single turn of the encoder, the pattern changes with every position.

Interior of a multi-turn absolute encoder

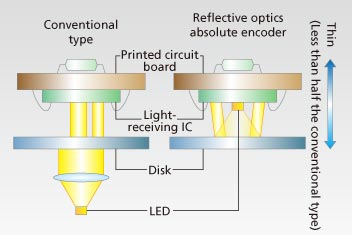

The reflective light-receiving sensor: By integrating the light source and the light-receiving part and enabling reflected light to be read by the light-receiving part, it was possible to reduce the height by more than half compared with the conventional type.

If a 20-bit resolution were applied to measure the Earth's circumference provided that the Earth's circumference were 40,000 km the encoder could detect the present position with an accuracy within 38 meters.

On production lines that are introducing industrial robots, further accuracy is being demanded through the promotion of factory automation, and the absolute encoder is being widely employed as a key component in this process. Furthermore, since high-precision control has become possible, robots are increasingly active not only in industry but in a wide range of fields. At times of disaster, rescue robots can squeeze into gaps in rubble that humans cannot enter and search for victims. Humanoid robots have polished their kinetic functions and evolved from walking to running, thereby drawing even closer to the movements of human beings. On the front line of robot technology, the absolute encoder is supporting the movements that we are demanding of robots from the base.