Nikon Announces the NSR-SF150. New Platform Provides Improved Overlay Accuracy and Superior Throughput

November 20, 2006

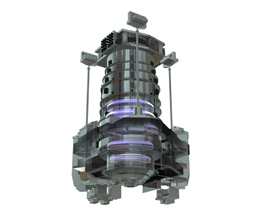

Nikon Corporation (President: Michio Kariya) has developed the NSR-SF150, a scan-field i-line stepper that delivers powerful performance for non-critical layers in mass production of next-generation memory and microprocessors. The SF150 is based on a new platform that uses Nikon's Skyhook Technology, which enables the projection lens to be suspended from the body and isolates it from the floor, greatly reducing vibration levels. The system also incorporates a new high-throughput wafer stage design with reduced weight and increased speed. Throughput for 300 mm wafers has been increased to 180 or more per hour, a nearly 54% improvement over previous models. Improved vibration control, air flow, and temperature control in the chamber provide far superior overlay accuracy. Sales of the system will start in the second quarter of 2007.

Sales Summary

| Product Name | Nikon Step-and-Repeat System NSR-SF150 |

|---|---|

| Sales launch term | Second Quarter 2007 (April to June of 2007) |

Development Background

In January of 2000, Nikon developed the NSR-SF100, the first i-line scan-field stepper in the industry designed for mix-and-match solutions with DUV excimer steppers. It was optimized for exposure of non-critical layers, which account for approximately half of all layers. The system used leading-edge lens technology to achieve the same wide exposure field (26x33 mm) as DUV scanners, making it ideal for mix and match applications. Its design offered superior throughput and reduced the number of exposures required per wafer. The NSR-SF100 and its successors contributed substantially to improving productivity and reducing the total investment costs of manufacturing lines. To date, more than 300 SF series steppers have been sold.

With the new platform and Skyhook Technology, the new NSR-SF150 is able to achieve significant improvements in both overlay accuracy and throughput.

Main Performance Features

| Resolution | 280 nm or better |

|---|---|

| NA(Numerical aperture) | 0.62 |

| Light source | i-line (wavelength 365 nm) |

| Projection magnification | 1:4 |

| Exposure field | 26 x 33 mm |

| Overlay accuracy | 25 nm or better (M + 3 σ) |

| Throughput (per hour) | 300 mm wafers: 180 or more wafers (exposure does 200 mJ/cm2) |

Main Characteristics

- Superior throughput

The combination of the optimal platform for steppers, the Skyhook mechanism, and the reduced weight of the wafer stage has realized great reduction in vibrations as well as increased stage speed. The SF150 boasts superior throughput of 180 or more 300 mm wafers per hour, an approximate 54% improvement over previous models.

- Greatly improved overlay accuracy

In addition to implementing the Skyhook platform, this step-and-repeat stepper employs a countermass for the first time. Furthermore, an overlay accuracy of 25 nm or better (an approximate 30% improvement over previous models) is achieved by reviewing the air conditioning duct layout and stabilizing the air within the chambers, as well as by succeeding in eliminating the reticle stage.

- Low Cost of Ownership

A low initial capital cost, coupled with high throughput and a smaller fab footprint gives the NSR-SF150 the lowest overall cost of ownership

Skyhook mechanism

- The information is current as of the date of publication. It is subject to change without notice.