What are the optical characteristics of cosmetics using nanotechnology?

Has the introduction of this system changed the cosmetics development process?

In present-day cosmetics foundations that adjust the color of the skin, many substances are used that perform color development by means of thin film interference, among which are those that use structural color development. Micronized pearl-colored raw materials that are used as ingredients in foundation raw materials appear white when scattered, but appear blue or red when the particles are applied to a substrate and lined up in one direction.

Traditionally, the development of cosmetics products has consisted of a sequence of manufacturing trial and error. The method that is used to determine good products that will fulfill the aim of creating a beautiful or young look is to repeatedly search for an ingredient, prescribe and evaluate it, and then try the next one. In the course of this process, a researcher relies on his or her intuition, which cannot be quantified, and there is no substitute for repeated trial and error. Given the requirement to come up with a product of some description within a fixed development period, compromise is inevitable.

If you can quantify an image of beauty or youthful looks, you can use a more intelligent method. For example, suppose the aim is to recreate beautiful skin (to make the customer look 10 years younger). Having set this as the target, the first step is to investigate what it is that changes and what it is that diminishes as someone ages. Then, since we know that the skin's apparent color differs when seen from certain angles, we will be able to see how ingredients ought best to be used to produce color, so as to enable the cosmetics to make up for the deficiencies.

With the multi-angle image capturing system, we first compare a person with beautiful skin and a person with ordinary skin. Under conditions in which the maximum amount of light is being reflected by the surface of the skin, we can see that the skin's luster varies. The beautiful skin partially absorbs light, and this brings out its color. For the ordinary skin, however, the color of the lighting is reflected unchanged, and the skin gleams white. Accordingly, we have developed a pearl-colored raw material that performs structural color development and makes up for deficiencies in skin color at certain angles only, in order to reproduce and bring out a brilliant skin color in the areas where the skin gleams with a white luster.

The term “structural color” refers to a color that is perceived due to a microscopic structure in the nanometer to micrometer range (close to the wavelength of light), such as a thin film or a regular pattern of bumps formed on the surface of a material. Light is reflected and bent in a complex fashion, and only specified wavelengths (or colors) are intensified, yielding the color that is seen. It is structural color that causes the light that strikes the recording surface of a compact disc (CD) to appear iridescent, and soap bubbles to appear to be colored. It is not the color of the material itself that is perceived—the perceived color changes as the light's angle of incidence changes. Hence, when a structural color is used on the skin, it does not appear smooth but has a three-dimensional effect.

For some time, skin color has been adjusted by putting pearl-colored raw materials available on the market in foundation. Now that we understand this mechanism, however, it is easy to design materials. Using the principle of structural color to carry out color development allows us to use simulations to make predictions.

Please tell us about cosmetics that use structural color.

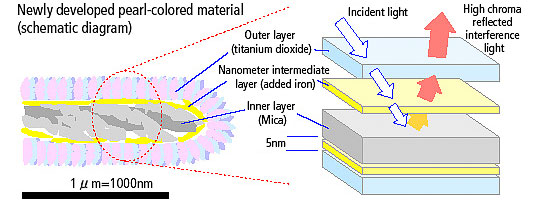

The pearl-colored raw material consists of mica particles covered in a thin film of titanium dioxide (TiO2). The thickness of this film is less than the wavelength of light, and color development results from the interference between the light reflected off the surface of the film and the light reflected from the inner surface of the film.

Since light interference is involved, in theory the thickness of the film and the color development ought to be governed by a mathematical formula. However, the results for simulations and the results for the actual materials were different. This means that the mathematical formula that has been widely used up until now proved to be inadequate. Some adjustments and improvements here brought the angular color characteristics and scattering spectrum into line with the simulation results. However, even this did not yield the brilliant gold color that expresses beautiful skin. Unless materials with a fairly high chroma are used, the effect is insufficient to make up for deficiencies in skin coloration. We achieved this by constructing an intermediate layer between the thin film and the substrate, and adding ferric oxide (Fe2O3) to it. Adding ferric oxide changes the refraction index and causes certain wavelengths to be absorbed. By incorporating all these complex conditions, we discovered from the simulations how to fabricate materials that would yield the brilliant gold color.

- The principle of thin film interference

- Some of the ordinary (white) light is reflected from the surface of the thin film, while some enters the interior of the thin film before being reflected back out agein. The light reflected from the film's surface and the light reflected from inside the film are out of phase with one another (that is, the light waves that comprise the beams are out of phase), and the interference between them causes only certain wavelengths to be intensified, yielding visible color.

The next stage was fabrication of the material; however, our first attempt yielded red color development—not gold. This can presumably be attributed to discrepancies in the simulation. Since we had confidence in the results of the simulation, we speculated that the condition of the layer may differ from the design, and this yielded a substance whose performance matched the results of our calculations. Using this pearl-colored powder has enabled us to create a foundation which carries out structural color development that gives the face a brilliant gold color when viewed from the front, making for a light and beautiful skin color, and creates shades that are redder further round the sides of the face to accentuate its three-dimensional quality.

A schematic diagram of the new pearl-colored material developed on the basis of research using the multi-angle image capturing system, and a structural diagram. Specular reflection causes high chroma, due to the insertion of the nanometer intermediate layer.