Automating human assessments—the System for Measuring the Quality of Pearls

Please describe the System for Measuring the Quality of Pearls which has now been commercialized.

The structure and interference color of a pearl

There are five standard criteria that are used to judge the quality of pearls: color, luster, nacre, blemish, and shape. Referring to a sample chart, skilled certified pearl appraisers evaluate each pearl by eye based on these criteria, and then determine its grade. Although the value of a pearl varies greatly according to its grade, it is not easy for an ordinary member of the public to discern differences in quality. This project was spurred by the idea that it should be possible to measure these differences in quality.

The two most important evaluation criteria are "luster" and "nacre". The term "luster" refers to the texture of the surface, and this can be quantified by means of a technique known as "high dynamic range (HDR) imaging," using multiple exposures.

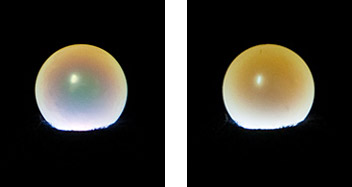

The term "nacre" refers to the characteristic interference color of a pearl. In pearl cultivation, a nucleus is inserted into the shell. In due course, a translucent layer known as the "nacreous layer," which consists of almost one thousand strata, grows around the nucleus. Exposure to light causes interference in this nacreous layer and the nacre—or interference color—becomes visible in the form of faint coloration from mother-of-pearl. The center of a good-quality pearl shines with a gentle green light, but if the nacreous layer is thin and brittle it will emit a faint white light. In the past there was no way to quantify this interference color and certified pearl appraisers would evaluate it by eye.

Sample chart for quality assessment. Certified pearl appraisers judge the grade of a pearl by comparing it with the pearls on this quality assessment sample chart.

(Photograph: Visual Perception and Cognition Laboratory)

Difference of the interference color between the good quality pearl (left) and poor quality pearl (right). Both pictures were taken with light from the bottom of the pearl.

When we investigated pearls by exposing them to various wavelengths with the ELS-VIS, we realized that the wavelengths at which the interference patterns show up most prominently differ according to the grade of the pearls—the higher the quality of the pearl, the shorter the wavelength of the light at which the interference pattern appears, and the lower the quality of the pearl, the longer the wavelength of the light at which it appears. This realization regarding the inter-relationship between the grade of a pearl and the interference pattern led to the development of our device.

This in turn led to improvements in aquaculture. In the past, improvements in aquaculture methods have produced no more than vague assessments based on human sensibilities, which were characterized by evaluations such as: "That was really good!" or "That was fairly good." Since it is now possible to make quantifiable assessments, information can be fed back into the production technology, as is the case with ordinary industrial products. If the device were to be installed in a store, customers could check the value of pearls for themselves right there.

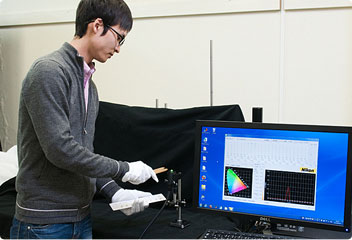

An experiment to measure the extent of the interference in pearls by exposing them to light of differing wavelengths using the ELS-VIS. The light wavelength is set using the software running on the PC.

The commercially available System for Measuring the Quality of Pearls, in which an LED is used as the light source instead of the ELS-VIS

(Photograph: Visual Perception and Cognition Laboratory)

So, research into perception reveals a variety of opportunities for practically implementing systems.

It is extremely rare for university research to immediately find practical application in the wider world. Since our research is directly linked to industry, however, I feel that it is highly meaningful. We are currently pursuing many collaborative projects with companies that are premised on the notion that they will become a reality. We are very grateful for the fact that offers still keep coming—both from home and abroad. Since we cannot cope with them all, however, we must, unfortunately, turn some down.

In the future I would like to conduct research into the nature of beautiful photographs that show texture. For example, if the comment were made that a photograph "lacked depth," would a photographer and a hardware engineer be able to share the same mental image of what that meant? Quantifying this would likely enable them to provide each other with feedback and lead to the manufacture of better cameras. I would also like to further pursue our research into functional light and continue engaging in research that will add value to LEDs and other forms of illumination across a greater number of industrial fields.

Posted August 2012