40x dispersion staining objective lens led to breakthrough

Was it not possible to take measurements with optical microscopes that did not use the dispersion staining method?

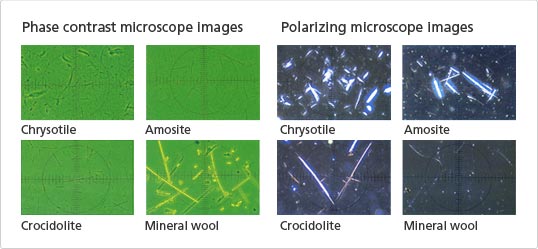

It was quite difficult, but we did take measurements with a phase contrast microscope and a polarizing microscope. The directive concerning specific dust concentrations related to asbestos issued in 1989 stated that a phase contrast microscope should be used to count fibrous material of over 5 micrometers in length and with an aspect ratio of at least 3:1. With this method, we can tell that the fibers are asbestos but we can't identify whether they are chrysotile, amosite, or crocidolite.

In observations through a polarizing microscope, we use a characteristic known as birefringence of asbestos. Fibers appear to have color or no color depending on the direction of each fiber's crystal. The observer needs to be highly skilled when carrying out polarizing observation. Also, because polarizing microscopes are specialized devices, they were not in widespread use.

Images observed through a phase contrast microscope and a polarizing microscope

So the dispersion staining method using a phase contrast microscope is becoming the leading method?

Guidelines issued by the Ministry of Health, Labour and Welfare in June 2005 use the dispersion staining method with a phase contrast microscope for qualitative analysis. Then, for samples where dispersed colors have been confirmed with a 10x dispersion objective lens, the lens is switched to a 40x dispersion objective lens in order to count the fibers with aspect ratios of at least 3:1 and the total number of particles.

The point is to use the dispersion staining method and a 40x dispersion staining objective lens. The technology for the dispersion staining method was established by Dr. Walter C. McCrone of the McCrone Research Institute in the United States. McCrone Microscopes and Accessories, Inc. sells 10x dispersion staining objective lenses, and we have been combining these with cargill oil to perform qualitative analyses on asbestos in bulk samples.

Since dispersion objective lenses were not available in Japan at the time, we approached Nikon. I think it was around 15 years ago that Nikon completed prototypes of 10x and 40x dispersion objective lenses and started selling 10x dispersion objective lenses. In the beginning, we used them for observations with a polarizing microscope, but when we tried using the 10x dispersion objective lens with a phase contrast microscope, we discovered we could also simultaneously confirm the dispersion color of asbestos irrespective of the direction of the fiber crystal. This was a major breakthrough. When we used a prototype of the 40x dispersion objective lens at the same time, we were also able to identify airborne asbestos fibers and count them. This led to the possibility that considerable progress could be made with the count analysis method.

Was Nikon therefore the first in Japan to make a commercially available dispersion staining objective lens?

Phase contrast dispersion microscope 80iTP-DSPH for measuring asbestos, and a 40x dispersion objective lens

After that, we were able to use the 40x dispersion objective lens of the time to establish a number of analytical procedures that would boost measuring accuracy. But since the NA (numerical aperture) value, one of the indices for indicating lens performance, was low, it was not possible to obtain a satisfactory resolution. I think it was around 2002 that we then went to Nikon Instech Co., Ltd. and asked them to try making a 40x dispersion objective lens with a high NA. The lens they made had an NA of 0.75. I remember being extremely excited at the remarkably clear dispersed color.

I think it was three years before asbestos became the problem it is today. If I remember correctly, Nikon wasn't expecting to sell many of these objectives after making them commercially available, but they still took the challenge seriously and did a wonderful job. Now, both of these lenses are becoming de facto standards, and in my mind they represent a splendid contribution to society.

Could you describe the airborne asbestos count analysis method that uses the dispersion staining method?

First, a filter is used to collect airborne dust. The filter is then fixed onto a glass slide for observation, and then the filter alone is burned with a low-temperature ashing device known as a plasma reactor so that the temperature can be held as low as possible. Due to the high fire-resistance efficiency of asbestos, it will remain on the glass slide.

The refractive index for chrysotile, amosite, and crocidolite is slightly different. After dripping refractive index liquid with the same refractive index as each of the three materials onto a slide and placing a cover glass over it, and observing it in the dispersion staining method, the color adheres only to fibers with the identical refractive index, making them visible.

So you can identify whether the fibers are chrysotile, amosite, or crocidolite, and you can see the shapes of the fibers, too. What is the principle by which only asbestos matching the refractive index is indicated by the dispersed color?

Light has a property of dispersing when it passes through media with different refractive indices. This is due to the fact that the shorter the light's wavelength, the higher the refractive index, and the longer the wavelength, the lower the index. Sunlight is split into seven colors when it passes through a prism. Since the refractive indices of a prism and air are different, dispersion occurs at the boundary where they meet.

With a phase contrast dispersion microscope, only light of a wavelength that matches the sample (asbestos to be observed) and the refractive index liquid continues straight ahead without being dispersed. In the dispersion staining method, only the light that is not dispersed but goes straight ahead is removed, and the sample is observed in the combination colors of the spectrum of remaining wavelengths. Therefore, it is possible to differentiate between chrysotile, amosite and crocidolite, allowing individual fibers to be identified and selected for observation.

- Process from white illumination to color dispersion

- Only the wavelength (color) that matches the sample and the refractive index of the refractive index liquid is removed from the color (white light) of the light source of microscope being used in the observation. The sample can be observed in the combination colors of the spectrum as an optical total sum of the remaining wavelengths.

The analyzer also seems to be your original technology. What sort of role does it play?

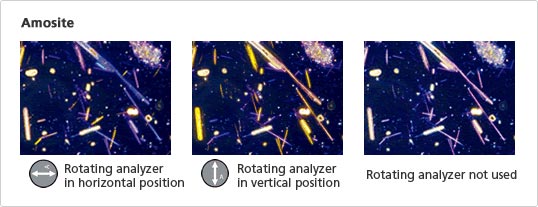

Rotating analyzer for asbestos

I've already explained that asbestos can be observed in a polarizing microscope. Since asbestos is a natural mineral, it has birefringent characteristics. Observations that use an analyzer (polarization plate) take advantage of this characteristic of asbestos. In the dispersion staining method, since differences in color occur as a result of different refractive indices, we make our observations based on the differences in color. However, if synthetic fibers with a refractive index close to that of asbestos are also present in the sample, the dispersed light from those fibers will be extremely close in color to the asbestos.

In such cases, it is possible to find out if birefringence is occurring or not by rotating an analyzer at a certain angle. We can determine if it is asbestos by the changes in the color being dispersed. The discovery of this method of observation using an analyzer occurred accidentally when the color being observed didn't look the way it usually did, and when we checked to see what was wrong, we discovered that the polarization plate was still attached. The Nikon person in charge who saw this said they could use the idea and they made the analyzer into a device that could be rotated at any angle. This became an extremely effective method of observation. We observe samples roughly in the dispersion staining method, if there is a sample that is stubbornly difficult to identify, we can use the analyzer to confirm identification. If the sample is observed only in a polarizing microscope, each fiber needs to be observed individually by rotating the stage.

The phase contrast dispersion microscope for observing asbestos has undergone various changes to become what it is today, hasn't it? Do you still have any further expectations for this microscope?

I am very grateful for Nikon's development of the world's first 40x dispersion staining objective lens, providing the idea of the rotating analyzer, as a researcher working at the frontline of these developments. To further improve measuring accuracy in the future, I would like an auto-stage to become standard equipment.

At the moment, we make observations of a single sample while changing the view field, but I think it would be very handy if it were possible to reproduce the process exactly. This would be especially useful when teaching observation methods to a number of people. In other words, when observing the same sample, if counting the same number of asbestos fibers in the same view field cannot be repeated, the data cannot be considered reliable. This feature could also be useful at seminars and in other situations where training in observation methods takes place.

Also, it would be nice if the auto-stage could keep the temperature of the sample at 25°C. The refractive index liquid is extremely sensitive to temperature change. I humbly urge Nikon to work on this. Besides the auto-stage, I look forward to the development of microscopes that are easy to use and meet the needs of the workplace.

Posted March 2006